Electrical contact exists wherever

the electricity is turned on and off.

Electricity is essential for our daily lives. There are various types of electrical switchgear, which conduct or disconnect various volumes of electricity. Chugai Electric Industry Co., Ltd., as a pioneer in electrical contact manufacturing, has developed electrical contact materials that correspond from low current to high current for all fields, then process them into various shapes according to customer’s application.

Vessel

Vessels are required to operate with high accuracy and precision at all times, even in rapidly changing environments. Our technology that allows us to manufacture from raw materials is highly evaluated and adopted.

Railroad

Electrical contacts are used in various units such as lighting, air conditioners, traction motors, control devices, and security devices in railways, which are important public transport for commuting to work and school. Chugai Electric Industry Co., Ltd.’s technology has been cultivated over the years and can support safe and comfortable train operation.

Commercial facility

Along with the development of large-scale commercial facilities, our products are used in circuit breakers, switches, and also control systems to create a comfortable space.

Aircraft

Our “electrical contacts” are used in the aircraft which not only require comfort in the cabin, but also high quality in their cockpits and control systems.

Skyscraper

In high-rise buildings that require a huge number of lighting equipment, air-conditioning equipment, communication equipment, and control systems, our “electrical contacts” are playing an active role behind the scenes.

School facility

Electrical contacts are also used in many schools and facilities, such as large lighting in classrooms or sports facilities, and circulation systems in swimming pools.

Lighting

Our “electrical contacts” are also made into shape according to customer needs and used in LED lighting equipment.

Circuit breaker

Our “Electrical Contacts” are used in circuit breakers which require safety and accuracy in cutting off the current since long ago.

Traffic light

Our “electrical contacts” with high reliability are also used in important traffic signals for controlling the traffic of roads and railways.

Home appliances

Our highly reliable “electrical contacts” are incorporated in home appliances such as air conditioners and microwave ovens that require high durability, low cost, and safety.

PC/mobile device

Our “electrical contacts” are used in PCs, smartphones, and tablets which are required to be built into limited size or space. This is because our technology allows us to make the “electrical contacts” into various shapes with different methods.

Car

Our “Electrical Contacts” are incorporated in every part of car, such as engine control units, air conditioners, navigation systems, and batteries.

Factory

Our “Electrical Contacts” support high productivity and quality reliability in various parts of the production line that systematically produces a variety of products.

Pursuit of safety and high production control

Chugai Electric Industry Co., Ltd.’s products are manufactured in-house,

from material melting to contact polishings.

We fulfill customer requirements by integrating high quality control and high R&D capabilities.

We always strive for technological innovation and the future of electrical contacts.

Material mixing/melting

One of Chugai’s greatest strengths is our custom-made material manufacturing technology, from material mixing to melting. We are able to manufacture silver alloys according to customer needs. All the mixing and melting processes are controlled in the Kanagawa factory (mother factory).

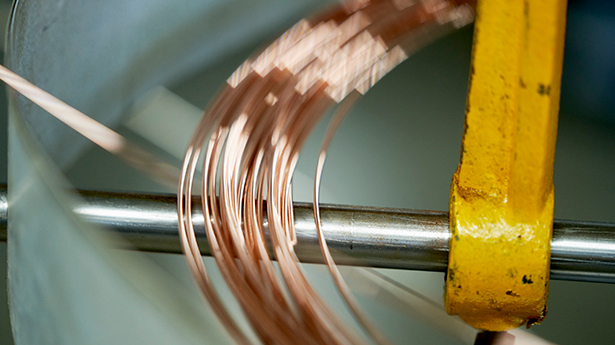

Material processing

The melted material is processed into wire or disc material before contact forming. Until the material processing, the processes are performed in the Kanagawa factory, then the material is shipped to each contact forming factory.

Contact forming

In addition to our main product, rivet contacts, we also provide disc contacts, tape contacts, inlay contacts, top lay contacts, etc., by using different manufacturing methods to provide products that fulfill customer specifications. We also make assembled contacts that are joined with base metal by using our own know-how. We can weld(furnace brazing, carbon brazing, direct bonding, etc.) or stake the contact onto the base metal.

Polishing/plating

Even in the important polishing process that affects product accuracy and reliability, our special technology delivers safe and high-precision products. As an electrical contact manufacturer, we use plating technology based on over 80 years of experience to improve the corrosion resistance and reliability of our products.

Inspection/delivery

In the final inspection process, we manage to deliver high-quality products based on the quality management system.

Product Inquiries CONTACT